Steel Strap & Seals

For heavy packages or sharp-edged packages, steel strapping is an extremely suitable packaging method. Steel Strap is used in industrial applications that require a strong, resilient, and easy-to-handle material for use in harsh and demanding environments. It is long-lasting and can withstand extreme temperatures, dust, vibration, moisture or dryness, and UV radiation.

Steel straps are characterized by thermal stability and high strength, so their application is mainly in the metallurgical or timber industry. Packaged item is lined around by the strap and then the strap is tightened by a strapping hand tool or tensioner. The joint can be made by cutting unit for steel strap or by using metal buckles.

Steel Strap Supplier - Bahrain

We are one of the top suppliers of steel straps in Bahrain, Saudi Arabia, Oman, and Egypt. Steel is the strongest material that is used in the packaging industry. It’s used for heavy-duty wrapping and packaging and is best used where no stretch is required. We offer a large selection of stainless steel banding straps that come in all grades and sizes. All our steel strap banding products come with certification to ensure that the banding clips and buckles conform to your project specifications.

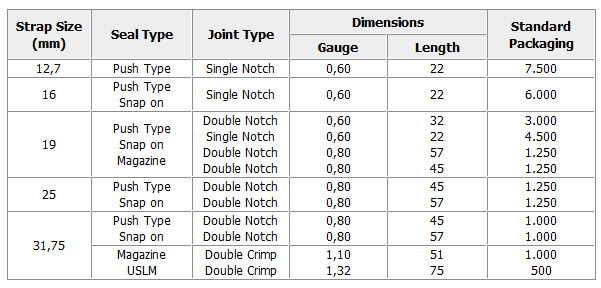

SITCO has two basic types of steel strapping: Regular duty and High tensile. Each is produced to meet the various demands of a particular range of applications. And for each strapping type, there is a selection of sizes and finishes which matches the most suitable for that application.

All steel strapping finishes are treared with a wax coating. This lubrication allows the strapping to flow smoothly in automatic, tools and around corners of products.

Application Of Steel Strapping:

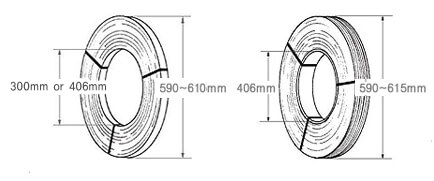

Wound Type

Inner Diameter For Strapping

Color Finishes

Packing

Stack On Pallet

Strapping Seals Distributor Bahrain

We can contribute to the product presentation of our clients by printing the corporate logos on the Ares Seals enabling their product to be distinguished from the others. We have the appropriate seals to tension the straps good enough for proper packaging.

SITCO is offering high quality metal seals to be used with steel strapping to ensure proper joint strength. The choice of a specific steel seals strap is often most strongly influenced by the type of strapping machine selected to apply it.There are five standard types of steel strapping seals that are available. Each type of metal seal is designed for a specific type of application.

- OPEN-FLANGE METAL SEALS

- SNAP-ON METAL SEALS

- THREAD-ON METAL SEALS

- MAGAZINE METAL SEALS

- PUSH-TYPE METAL SEALS

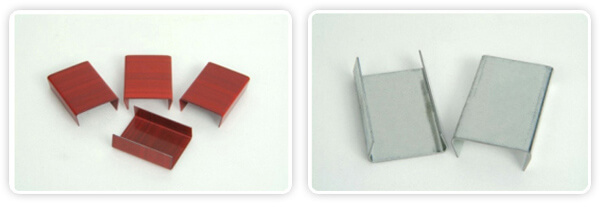

Snap-On Type (Open) Seals

Snap-on metal seals are made for both poly and steel strapping applications. These seals eliminate the need for pre-threading a seal, which helps speed up the strapping closure process. Fast and easy to use, open seals can be placed over the strap before or after tensioning.

Thread-On (Closed) Seals

This type of metal seal must be pre-threaded over the strapping ends before you tension them. Once the tensioning process is complete, then you will finish the joint by closing the thread-on seal. These seals are often used for loads such as bales and bundles. Thread-on seals are commonly used for larger strap sizes.

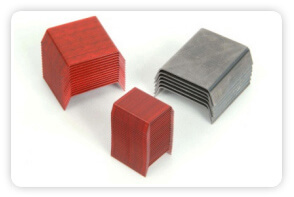

Magazine Seals

Magazine Seals are made from high strength carbonized steel. Designed to secure regular-duty steel strapping. Held together by interlocking nibs. This development allows loading partial stacks into magazines of seal feed combination tools.

Push-Type Seals

Push metal seals are able to withstand higher stress because of the overlapping metal flanges, or edges. These seals are pre-threaded onto overlapping strap ends. As the tensioning process begins, the nose of the tensioner is pushed against the seal. These are used mostly in steel strapping applications for heavier load containment.